Elora Plant Design

How do

we do?

How do we do?

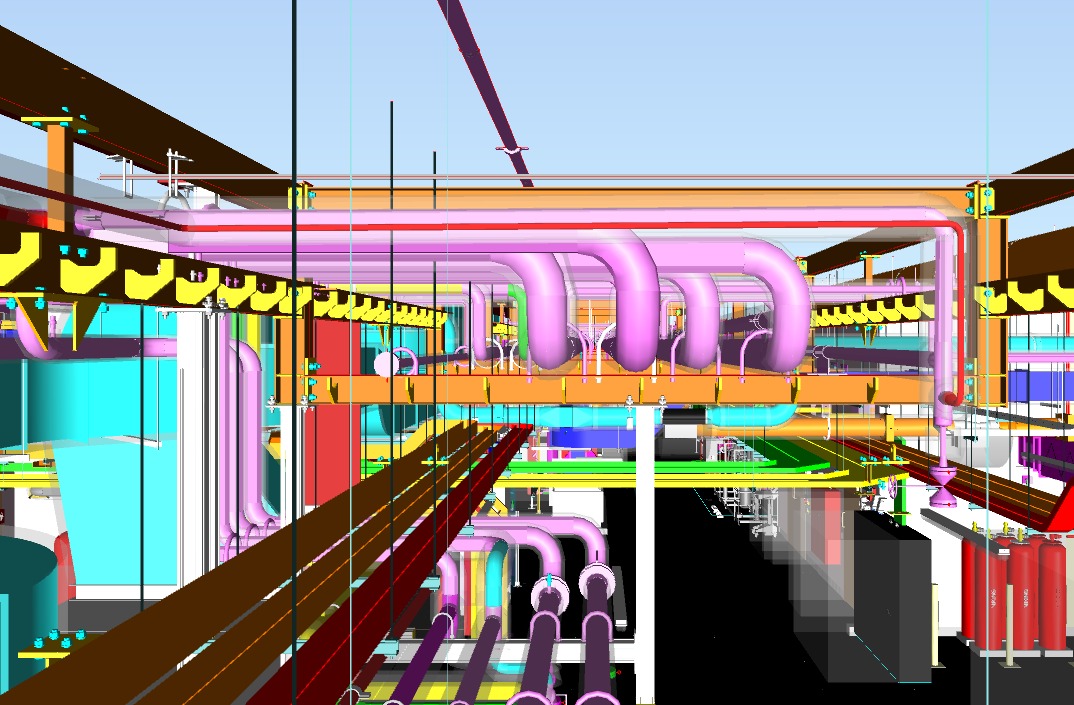

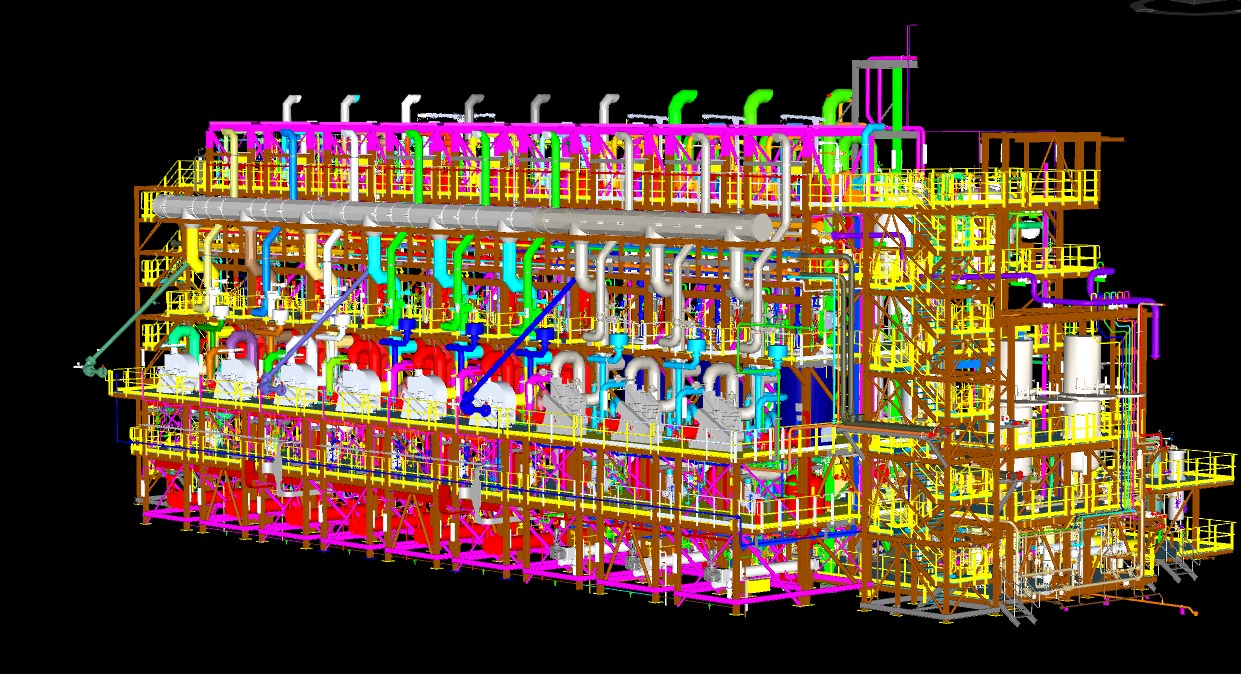

Autodesk Plant 3D

Plant 3D projects creation and management (SQL & SQLite).

Project setup (Folders structure, Isometric templates, databases, revision management, XML files config…)

Material catalogues and spec loading (based on Client’s Piping Material Classes and Standards).

Development of piping support parametric catalogue using Python

Point Cloud and reference models loading into our Plant 3D Project by using AutoDesk ReCap.

3D modeling of equipment, main steelwork and civils, and special piping items.

Piping routing and supporting of any system (incl. Jacketed or sloped lines...)

Ortho drawings (Piping plan, Piping support plan, steelwork and foundations equipment location drawing...)

Isometric drawing, flowcheck against P&ID and accurate MTO production

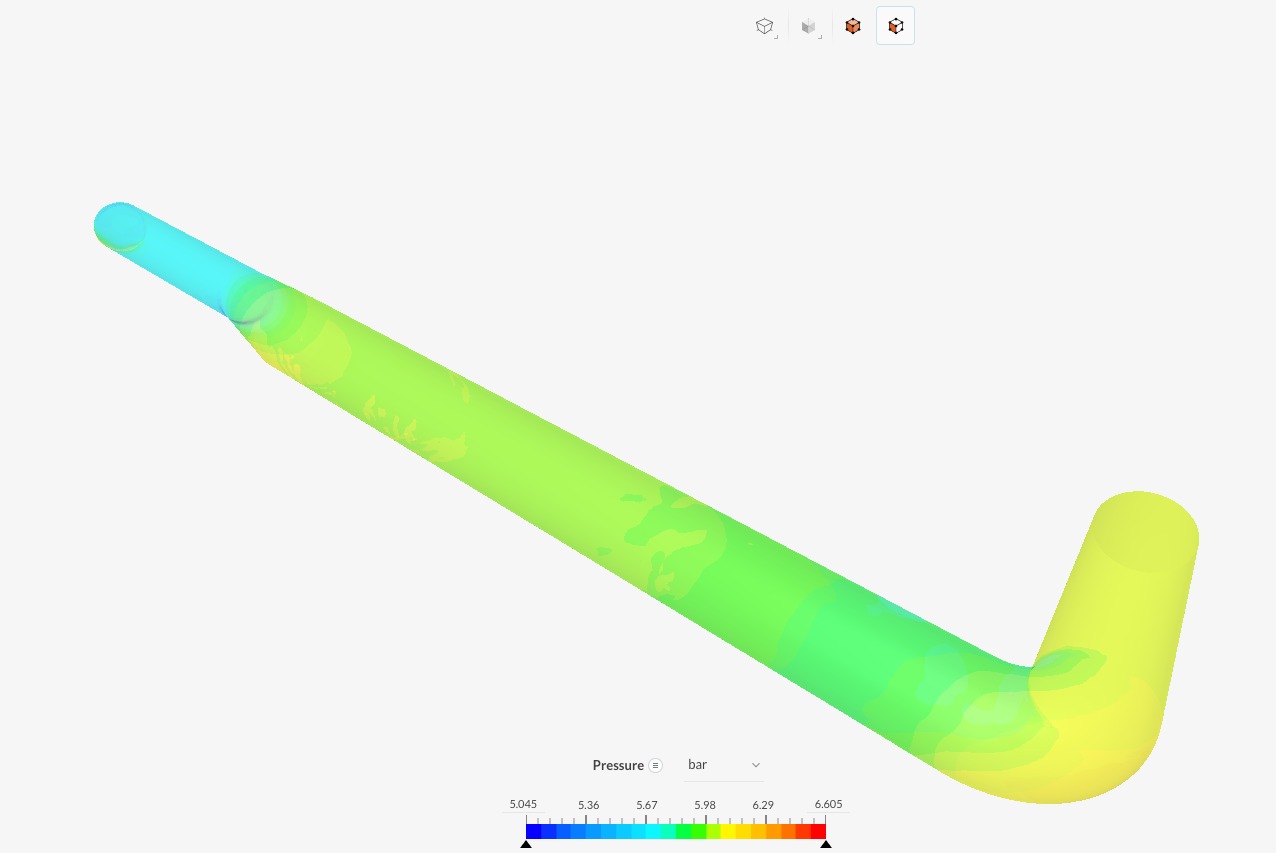

Speed evolution of a fluid in a pipe over 1000 seconds

PLANT LAYOUT PLANNERS

PIPING AND EQUIPMENT DESIGNERS

STRESS AND PIPE SUPPORTS

ENGINEERS

Autodesk Plant 3D

Caesar II

Autodesk Navisworks Manage

Who we are?

Elora Plant Design

Everything the Client wants, just better

Elora Plant Design is a spanish limited company specialized in remote-based Piping and 3D modelling jobs working for several European companies.

How do we do?

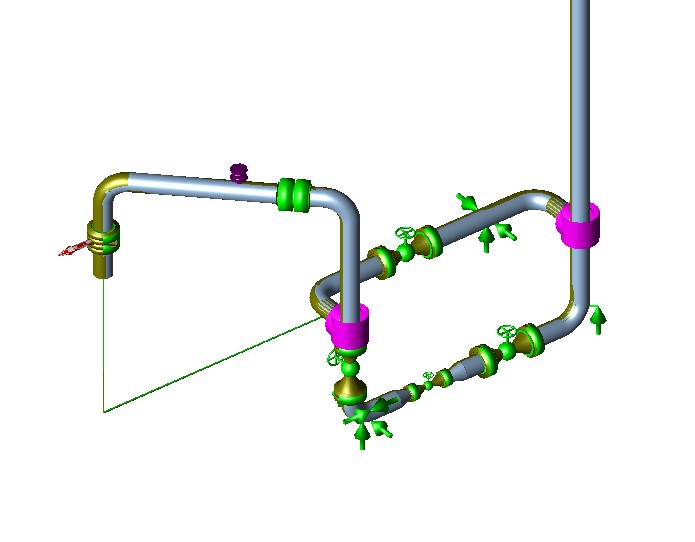

Caesar II

3D simulation (CAESAR II) of any kind of piping system, equipment, piping suportation, or structure, manually or by using PCF files from the design software.

Compliance with all the client’s requirements (pipeline routing and temperature and pressure conditions, material, insulation, wind or seismic loads, etc…) and with the standard used (ASME B31.3, B31.1, B31.4, B31.8, CODETI, EN13480, …)

Static analysis (to check over-stresses, flange leakages, nozzle loading, displacements, code compliance, reaction forces reporting, etc…) Dynamic analysis (modal analysis, time-history, water hammer, slug flow, etc…) when required.

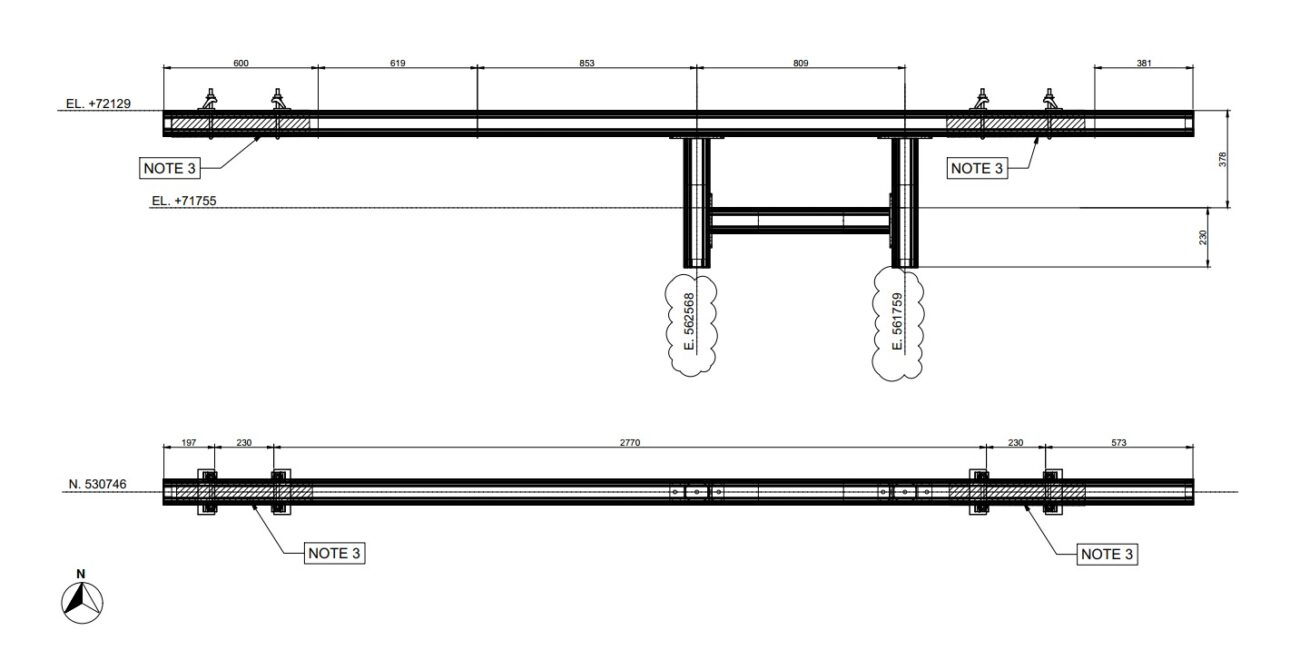

To ease the piping supportation, we can produce the stress isometrics by using CAESAR II software (with custom data and custom drawing border adapted to the client requirements), or even using a Plant3D style specifically created to allow connectivity with the information generated by CAESAR (loads, node numbers, support type and symbology, etc…)

Piping supports (rigid, springs and special type) final definition and calculation. Stress reports production (outputs from CAESAR II) or descriptive report when required.

How do we do?

Autodesk Navisworks Manage

+ ReCAP

Creation of dynamic 3D Model.

Reference models integration.

Clash check.

Model review and design issues management (tags).